Boston Dynamics Atlas wins CES 2026 award as Hyundai touts factory AI robotics

TL;DR

On January 9, 2026, Hyundai Motor Group said its Boston Dynamics Atlas humanoid robot won CNET’s Best Robot award in the Best of CES 2026 honors. The group plans to start deploying the next‑generation electric Atlas in its Savannah, Georgia plant in 2028, with broader rollout across global factories by 2030.

About this summary

This article aggregates reporting from 2 news sources. The TL;DR is AI-generated from original reporting. Race to AGI's analysis provides editorial context on implications for AGI development.

Race to AGI Analysis

Atlas winning CNET’s top robot award at CES 2026 is more than a trophy moment for Hyundai Motor Group; it’s a marker of how fast ‘physical AI’ is moving from lab demos into industrial roadmaps. The new Atlas is explicitly designed for factory work, with 56 degrees of freedom, 50‑kilogram payloads and an AI‑driven control stack aimed at real production lines. Hyundai’s plan to deploy the robot first in its US Metaplant, then across its global footprint, signals confidence that humanoids are ready to shoulder meaningful workloads rather than remain R&D curiosities.

For the AGI race, embodied systems like Atlas are where abstract intelligence meets messy reality. Training robots to handle unstructured, safety‑critical tasks in plants will force advances in model grounding, planning under uncertainty and human‑robot collaboration. If Hyundai and Boston Dynamics can show economically viable deployments at scale, it will pressure automakers, logistics giants and electronics assemblers to accelerate their own humanoid programs.

The competitive picture is also shifting. Chinese players like Unitree and Galbot are already shipping thousands of humanoids domestically, while Tesla, Figure and others chase similar industrial use cases. Atlas’ CES recognition gives Hyundai a branding win, but the real race now is who can turn these machines into platform businesses — with fleets of robots generating data that feeds back into ever‑smarter control and planning systems.

Who Should Care

Companies Mentioned

Related News

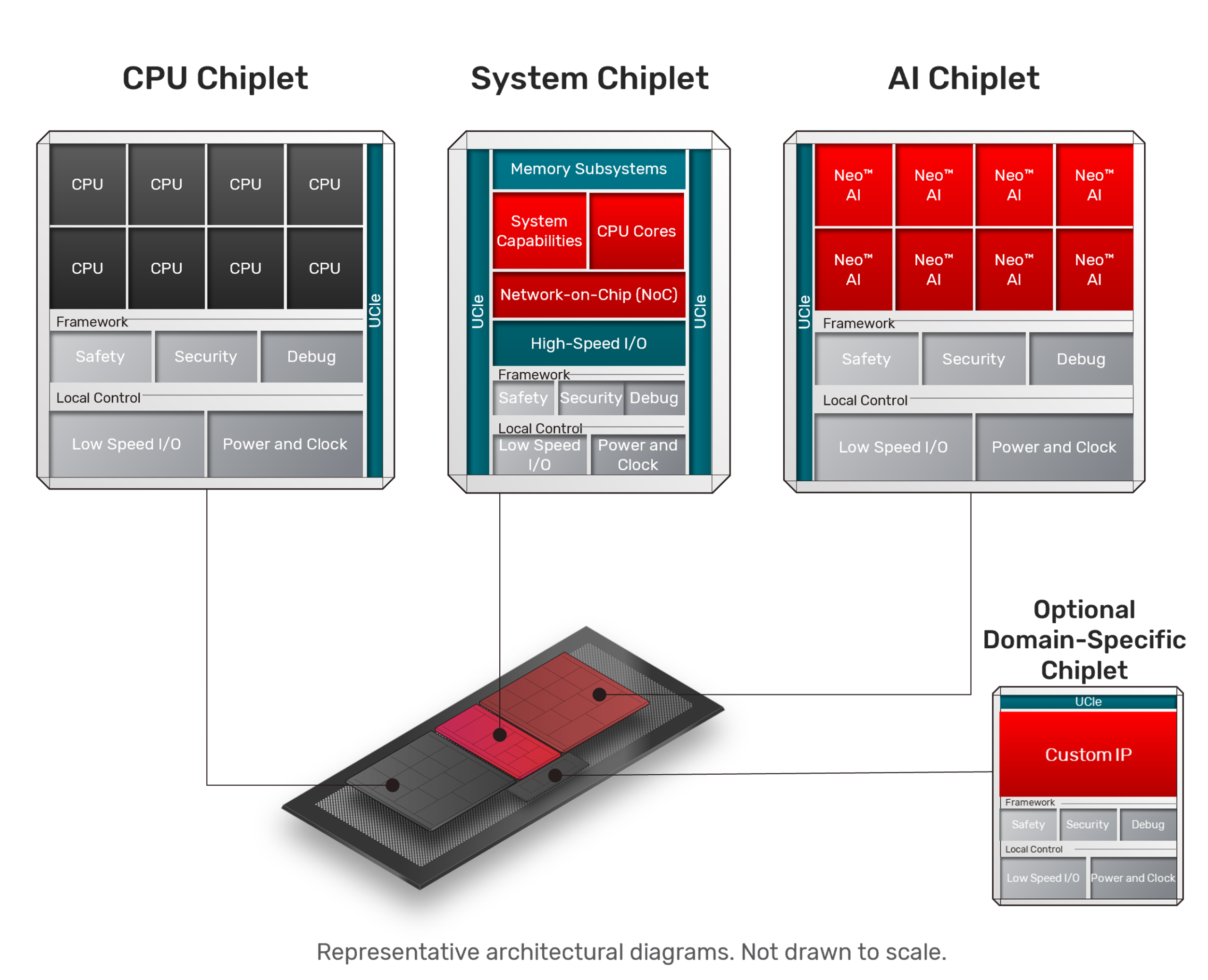

Cadence touts pre‑validated AI chiplet platform to speed custom silicon

TodayCyberPress flags 91,000 attacks probing AI deployments worldwide

Today

Yuwell showcases AI health ring and wearables at CES 2026 debut

Today